About

FDM is a professional yoga mat manufacturer and OEM factory, specializing in high-quality, fully customizable yoga mats and yoga accessories for global wholesale and private label clients.

Our product range includes standard yoga mats, travel mats, extra-thick mats for rehabilitation, guided alignment mats, as well as yoga blocks, straps, bags, and training accessories, supporting flexible bulk production and stable supply.

Owned Factory

FDM operates a 40,000㎡ production base with advanced automated lines. As a professional yoga mat manufacturer and factory, we produce up to 6,000 premium yoga mats daily, ensuring consistent quality and reliable supply.

OEM/ODM

Our professional yoga mat factory provides comprehensive yoga mat customization services for studio and brand clients, including custom thickness, materials, colors, sizes, surface textures, and personalized logo branding, helping you create distinctive, market-ready yoga mats.

LOW MOQ

We offer flexible ordering options to meet different business needs, from large-scale wholesale production of bulk yoga mats to small custom batches, with low MOQ starting at just 100 pieces for custom yoga mat designs.

Who We Are

FDMSport is a China-based yoga mat manufacturer and fitness equipment supplier, specializing in OEM and ODM production since 2015. We work with global fitness brands, retailers, gym chains, and e-commerce sellers, providing stable bulk manufacturing and customized product development.

Our manufacturing facility integrates automated production lines, in-house quality inspection, and standardized process control, with an annual capacity exceeding 2.16 million yoga mats. Core capabilities include controlled material sourcing, precision molding and lamination, surface texture and printing development, and consistency management for large-volume orders.

Compared with conventional yoga mat suppliers, FDM Sport provides full production support across the entire project cycle — including product specification review, material selection, sampling, mass production, packaging coordination, and export logistics management. All production complies with REACH and RoHS requirements to meet international market safety standards, while flexible MOQs accommodate both pilot programs and scaled retail orders.

We manufacture a wide range of yoga mats, including TPE yoga mats, PVC yoga mats, and natural rubber yoga mats, supporting multiple thickness options, surface finishes, and private label branding to match different market positioning and price structures.

Mission Statement

To support fitness brands and wellness businesses worldwide with reliable manufacturing of high-quality yoga mats, combining efficient production, responsible material selection, and practical customization solutions. We focus on delivering consistent product performance, compliance with international safety standards, and long-term supply stability for commercial and retail markets.

Vision Statement

To build a globally reliable yoga mat manufacturing business recognized for consistent product quality, stable supply capability, responsible production practices, and continuous process improvement. FDM Sport aims to strengthen long-term partnerships with fitness brands and distributors by improving manufacturing efficiency, product consistency, and technical capability over time.

Projects Completed

%

Positive Ratings

Members

Awards Achieved

What We Do

As a comprehensive yoga mat manufacturer, FDMSport specializes in producing diverse fitness mat solutions tailored to various market segments

Core Product Lines

Natural Rubber Yoga Mats

Biodegradable rubber construction with high surface traction and thickness options from 4–8mm.

Best suited for: non-slip yoga mats, hot yoga, studio use, professional training programs, and premium retail collections where strong grip and floor stability are required.

TPE Eco-Friendly Yoga Mats

Non-toxic and recyclable materials with lightweight construction (0.8–1.2kg) and balanced cushioning.

Best suited for: eco-friendly yoga mats, retail and private label programs, daily home practice, lightweight travel use, and kids yoga mats requiring soft touch and low odor.

NBR Yoga Mats

High-density foam structure with enhanced shock absorption and soft cushioning feel.

Best suited for: extra-thick yoga mats, rehabilitation and physiotherapy exercises, beginner training, kids yoga mats, and low-impact fitness applications requiring joint protection.

Cork Yoga Mats

Natural cork surface combined with stable backing material, offering antimicrobial properties and moisture resistance.

Best suited for: non-slip yoga mats, hot yoga, eco-focused product lines, boutique studios, and premium wellness brands.

Suede (Microfiber) Yoga Mats

Soft microfiber surface with moisture-activated grip and high-definition printing capability.

Best suited for: hot yoga and sweat-intensive practice, printed design collections, lifestyle retail brands, and premium anti-slip yoga mats with strong visual differentiation.

Acupressure / Spiked Mats

Textured surface design developed for muscle stimulation and circulation support.

Best suited for: wellness recovery programs, relaxation products, physiotherapy accessories, and home recovery retail lines.

Customization Capabilities

Material Selection: 10 material combinations including NBR, cork, suede surfaces

Size Customization: Standard (183×61cm) to extra-long (200×90cm) and custom dimensions

Design Options: Digital printing, embossing, laser cutting for logos and patterns

Color Matching: Pantone color matching system with 200+ standard colors

Packaging Solutions: Private label packaging, retail-ready boxes, bulk shipping options

Advanced Intelligent Manufacturing

Advanced Foam & Composite Manufacturing

- Precision Foam Extrusion: Temperature-controlled extrusion systems (±2°C tolerance) maintain stable material density across production batches, supporting consistent cushioning performance and long-term dimensional stability.

- Multi-Layer Co-Extrusion Technology: Enables single-pass production of dual- or multi-layer structures with different surface and base materials, integrating functional layers for grip, cushioning, and floor stability without secondary lamination processes.

- Custom Color Formulation & Mixing: Dedicated mixing and dispersion equipment supports Pantone color matching accuracy above 95%, ensuring color consistency and brand alignment across OEM and ODM production runs.

Advanced Surface Treatment Solutions

- High-Definition Printing & Branding: Supports digital sublimation printing up to 1440 DPI and durable screen printing processes verified for long-term abrasion resistance, enabling stable logo reproduction, multi-color graphics, and consistent brand identity across OEM production.

- Functional Texture Engineering: Embossing and debossing processes create surface textures, alignment markers, and grip patterns that improve positioning guidance, tactile feedback, and product differentiation without affecting material integrity.

- Hygiene & Surface Protection Treatments: Surface treatment systems support silver-ion and plant-based antibacterial agents to enhance hygiene control, odor resistance, and suitability for high-frequency studio and commercial usage environments.

Foaming

Engraving

Splitting

Packing

2015

Establish

Establish selling office in Wuhan with 3 people

2017

develop

3 Alibaba platforms and vertify 5 stars suppliers

2018

breakthrough

Established its own factory “Hubei Freedom Sports Co., Ltd.”

2021

professional

BSCl certified factory and supplies yoga products to supermarket chains: Aldi, Rossmann

2024

powerful

Established a new factory with more than 100 skilled workers

Business Model

FDM Sport operates a manufacturing-driven B2B business model designed for buyers who require stable quality, scalable capacity, and long-term supply reliability rather than short-term price competition.Our growth is built on four practical operating pillars: inbound customer acquisition, modular customization, controlled manufacturing, and repeatable order fulfillment.

1. Qualified Inbound Acquisition

We acquire customers through Alibaba International Station, our independent website, and professional outreach channels. Instead of high-volume traffic, we focus on attracting buyers with clear purchasing intent, such as distributors, gym operators, private label brands, and e-commerce sellers.

Product content highlights specifications, material options, MOQ, packaging standards, and real application scenarios. This filters inquiries upfront and improves conversion efficiency.

2. Modular Customization on Standardized Platforms

Our production is based on standardized molds, material formulations, and stable process parameters. Customization is applied modularly across size, density, color, surface finish, branding, and packaging.

This structure keeps costs predictable, lead times controllable, and quality consistent while maintaining flexibility for private label programs.

3. Controlled Manufacturing & Consistency

Each batch follows incoming material inspection, in-process dimensional control, density monitoring, and durability sampling. Batch traceability ensures consistent firmness, surface quality, and functional performance across bulk shipments.

Our quality system is built for high-frequency usage, retail replenishment cycles, and long-term supply programs.

4. Scalable Fulfillment & Logistics Integration

We support full container shipments, mixed-SKU consolidation, seasonal programs, and rolling replenishment orders. Carton design, pallet standards, and freight coordination are optimized to reduce handling risk and logistics cost.

Stable delivery performance improves buyer planning accuracy and operational efficiency.

5. Growth Through Repeatability

Our growth comes from customer retention, SKU expansion, and predictable reorder cycles rather than one-time projects. This creates stable capacity planning, transparent cost control, and sustainable partnerships.

Get Bulk Pricing & MOQ Details

Contact our team to discuss custom materials, branding options, and packaging solutions for your private label program.

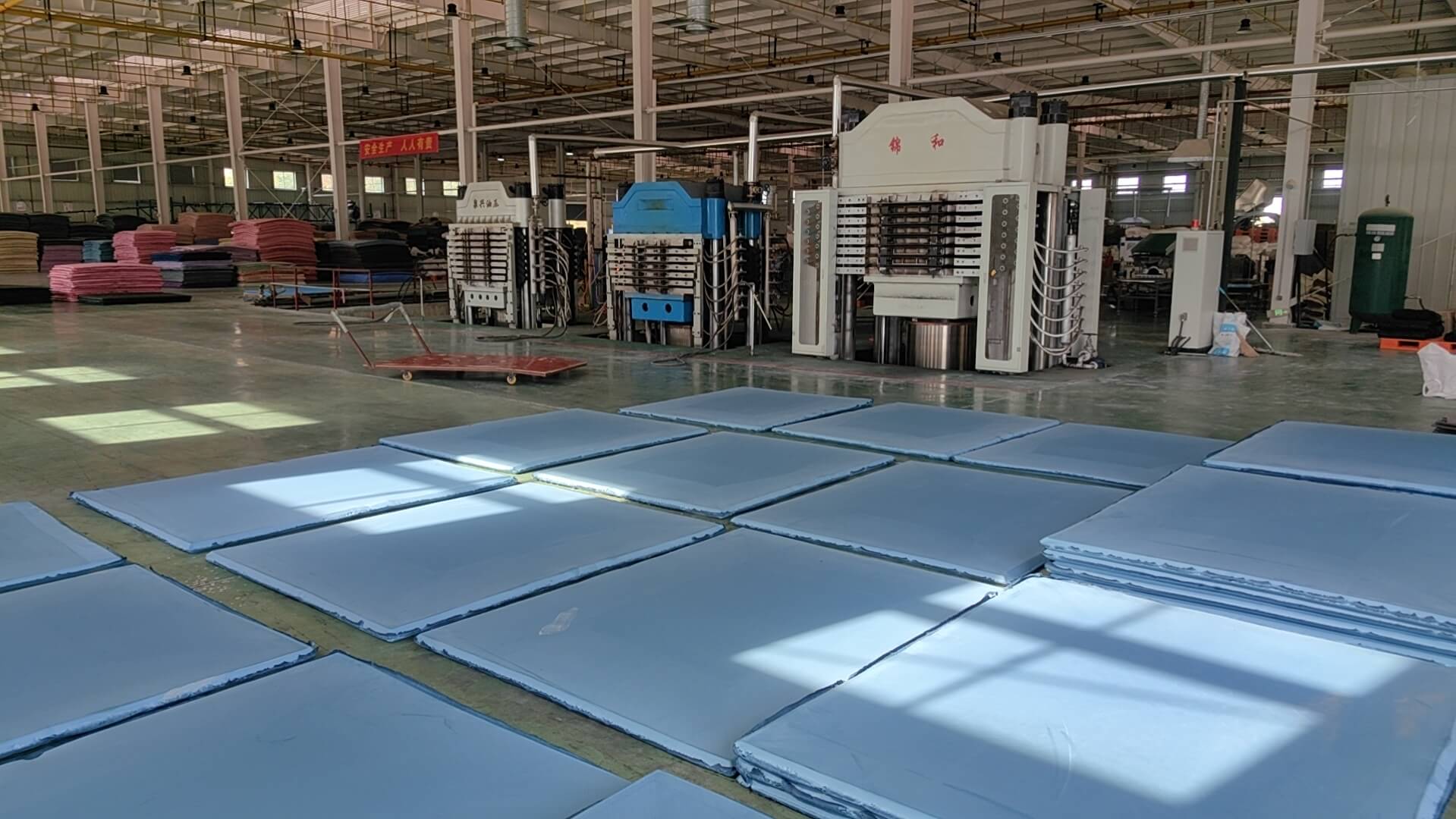

Our Yoga Mat Factory

Our 40,000 sq. ft. production facility, commissioned in 2018 and purpose-built for professional yoga mat manufacturing, operates as a vertically integrated yoga mat factory covering raw material processing, foam extrusion, molding, surface finishing, and automated quality inspection. The plant is organized with lean production zoning, including controlled material batching, temperature-regulated molding for stable density and elasticity, and advanced surface processes such as texture engraving, lamination, trimming, and anti-slip treatment, supported by automated inspection systems combining high-resolution visual scanning and mechanical stress testing for batch consistency in large-volume OEM and ODM production. Material flow is managed through conveyor systems and robotic handling to improve handling accuracy and throughput, while environmental controls include positive-pressure workshops, HEPA air filtration, and a closed-loop water treatment system achieving up to 90% water reuse to support regulatory compliance, stable process conditions, and long-term operating cost control.

Team Behind Our Success

As a professional yoga mat manufacturer with many years of experience in the sports equipment industry, we focus on the global development of yoga products, helping customers achieve an average annual sales growth of over 20%. We are highly familiar with mainstream market access regulations and sales channel operations across Europe, North America, and Asia, and have successfully expanded our partners’ presence to more than 5,000 retailers and e-commerce platforms, including Amazon, Target, and leading regional marketplaces. By integrating FDM patented technologies such as advanced anti-slip performance and VOC-free eco-friendly materials, we provide high-premium, customized yoga mat solutions, empowering brands to continuously scale with professional market insight and an agile, responsive supply chain.

Heysy

Management Head

Elaine

Southeast Asia Market Manager

Wendy

Head of North American Market

Nora

Head of European Market

How We Work

Raw Material

Mixing

Foaming

Splitting

Cutting

Composite

Pattern

Die cutting

Laser engraving

Rolling

Protecting Your Brand Reputation Through Manufacturing Precision

For businesses building brand equity through private label yoga products, consistency across production batches is non-negotiable. A yoga studio with 300 purple mats can’t accept batch #2 arriving in a noticeably different shade. Our quality systems ensure every reorder matches your brand standards exactly.

Color Consistency Technology

Pantone color matching system creates digital color profiles stored in your client file. Each production batch references these profiles, with color meters verifying ±2 Delta E tolerance (invisible to human eye). For critical brand colors, we maintain reserved material inventory preventing supplier variation between your orders. Before production begins, color samples are submitted to your team for approval – ensuring alignment before manufacturing 1,000 units.

Logo Reproduction Quality

Digital printing files are archived in cloud-based systems accessible for instant reorders. Vector artwork ensures logos scale perfectly whether printed on standard or extra-large mats. Print quality inspections check registration accuracy (±1mm), color saturation consistency, and ink adhesion strength. For sublimation printing, heat-press temperature and pressure are calibrated weekly against control standards. Laser engraving depth measurements ensure tactile consistency batch-to-batch.

Dimensional Tolerances

Automated cutting equipment maintains ±0.5mm thickness and ±3mm length/width tolerances across production runs. Monthly calibration against certified measurement standards prevents equipment drift. When yoga studios need mats stacking uniformly in storage racks, these tight tolerances matter.